Mr. Noriyuki Ozawa

Managing Director

From Malaysia to the World…

--- Continuously Promoting the UNION Brand to Global Markets ---

---Continuously Promoting the UNION Brand to Global Markets---

We would like to express our sincere gratitude for your continued support.

Thank you for visiting our website.

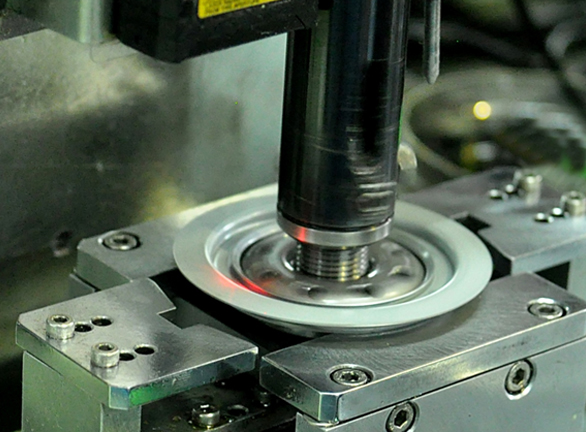

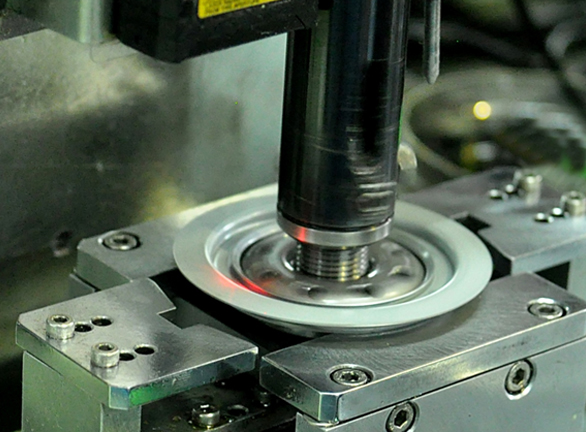

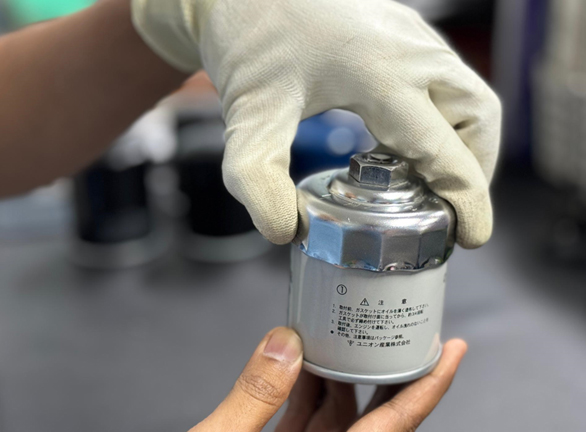

Union Sangyo Co., Ltd. was established in 1963 in Toyota City, Aichi Prefecture, Japan, and began operations as an automotive oil filter manufacturer in 1968. As a company with a foundation in steel plate pressing industry, we specialize in high-precision steel plate processing, such as deep drawing, which requires advanced technical skills.

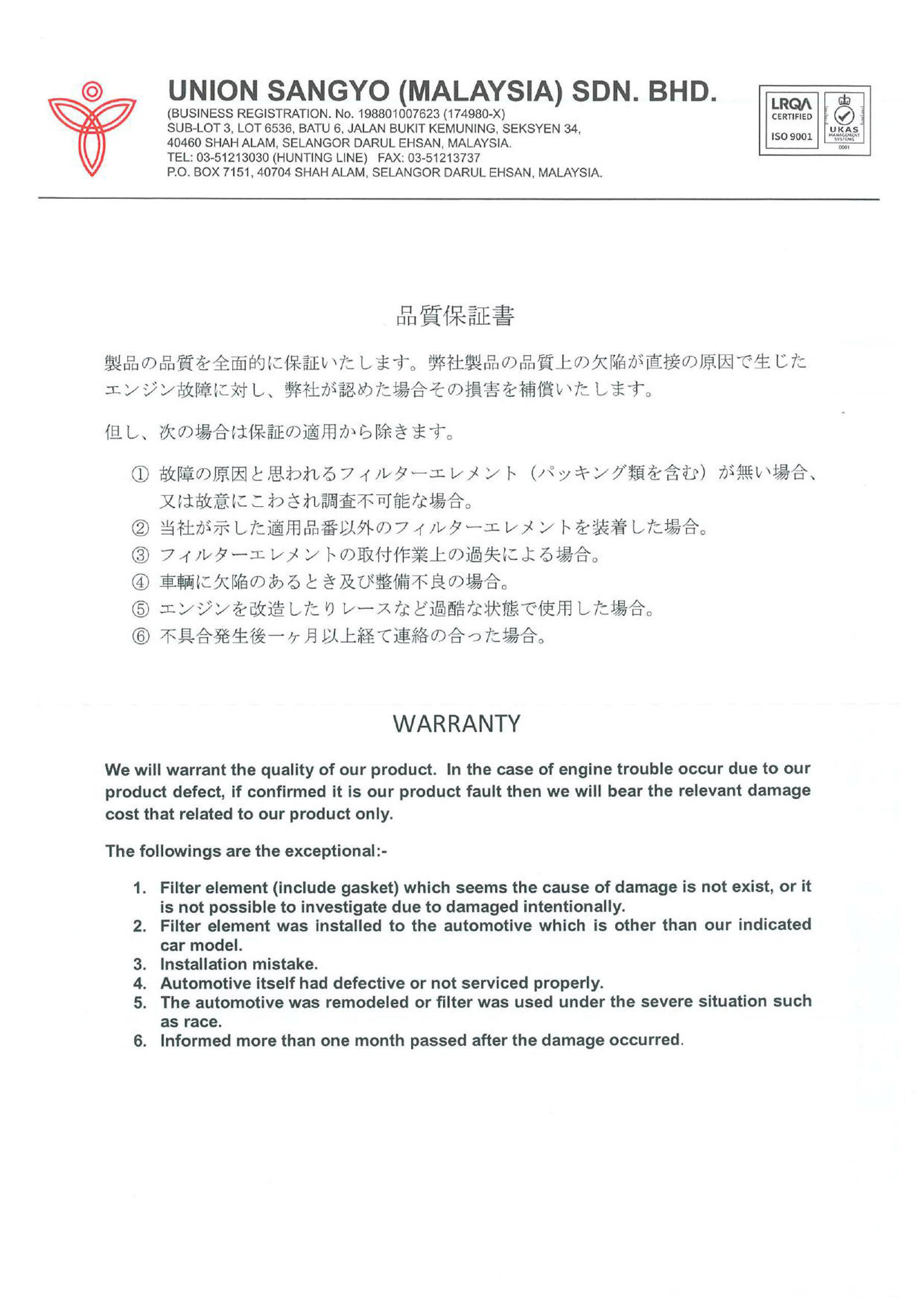

In 1990, we shifted our main production base from Japan to Malaysia and commenced operations at UNION SANGYO (MALAYSIA) SDN. BHD. in Selangor, Malaysia. In collaboration with both Japanese and local staff, UNION SANGYO MALAYSIA obtained ISO 9001 certification in 1999.

Our company adheres to both JIS and ISO standards, ensuring comprehensive quality management, production control, safety management, and overall business operations.

In 2019, we further achieved ISO 9001:2015 certification, reinforcing our commitment to higher standards in all aspects of management.

Today, we continue to meet the diverse demands of our customers, expanding beyond automotive filters to include filters for construction machinery, industrial equipment, agricultural machinery, motorcycles, and marine applications. Our distinctive “integrated production system” enables us to maximize performance and respond flexibly to a wide range of needs.

Guided by our corporate policy, we strive for mutual growth with our customers and suppliers, contributing to the advancement of the automotive parts industry and the realization of a prosperous society for the future.

We sincerely appreciate your continued support and guidance.

Our House Brand

Our Company

Vision & Mission

Our Vision

To be a global leader in the automotive spare parts industry, committed to maintaining the highest quality standards through innovative automation solutions. We aspire to set benchmarks in quality, trust, and efficiency, contributing positively to the automotive sector and society as a whole.

Our Mission

Our mission is to deliver superior automotive products that reflect the excellence of Japanese engineering, with a strong emphasis on quality and automation. By leveraging cutting-edge technology and continuous improvement, we strive to forge strong relationships with our customers, partners, and communities. We are dedicated to upholding our promise of providing reliable products at a competitive price, now and always.

KAIZEN Principle at Union Sangyo

At Union Sangyo, KAIZEN, the Japanese philosophy of “continuous improvement,” is central to our operations. We focus on making small, incremental changes to enhance our manufacturing processes, improve quality, and increase efficiency. By continuously refining our production methods and fostering a culture of open communication, we ensure our products meet the highest standards while adapting to market demands. KAIZEN drives our commitment to excellence, sustainability, and customer satisfaction, ensuring we “do it right the first time and every time.

Quality Policy

- [/] Global Market Share Position

- [/] World -class Quality Products

- [/] Bench-marked Productivity

- [/] Competitive Unit Cost

Milestone

1963

Established Union Sangyo Co., Ltd. in Toyota City, Aichi Prefecture

1968

Began operations at the Toyota Factory in Toyota City, Aichi Prefecture

1977

Began operations at the Tsushima Factory in Tsushima City, Aichi Prefecture

1988

Established Union Sangyo Malaysia Sdn. Bhd. in Selangor, Malaysia

1990

Began operations at Union Sangyo Malaysia Sdn. Bhd. in Selangor, Malaysia

1996

Established Mutsu Printer Sdn. Bhd. in Malaysia as associate company to produce packaging boxes

1997

Began business relations with a major German automotive parts manufacturer

1999

Union Sangyo Malaysia Sdn. Bhd. obtained ISO 9001 certification

2006

- Established Zendo Rubber Sdn. Bhd. in Malaysia as associate company to produce rubber part such as gasket , diaphgram and others.

- Organized the sales network into a system with headquarters, 3 branches, and 3 sales offices

2010

Began business relations with a major Japanese oil company

2012

Maromi Sangyo Co., Ltd. became a group company

2014

Established Gion Filters Sdn. Bhd. in Malaysia as associate company

2017

Union Sangyo Malaysia Sdn. Bhd. obtained ISO 9001:2015

2018

Launched Excel Japan brand to expand the product line and enhance global market presence

2020

Responded to the global COVID-19 pandemic by implementing safety measures and maintaining operational continuity to support automotive industry needs

2022

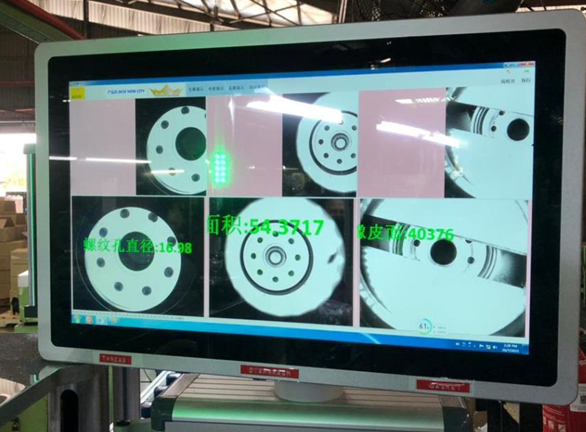

Introduced a new digital quality control system across production lines, enhancing precision and efficiency in product inspections

2023

Started business with well-known local car maker

2024

Completed a major upgrade of the Malaysian production facilities, integrating advanced quality control systems to uphold top-tier product standards

PRESENT

Union Sangyo continues to expand.

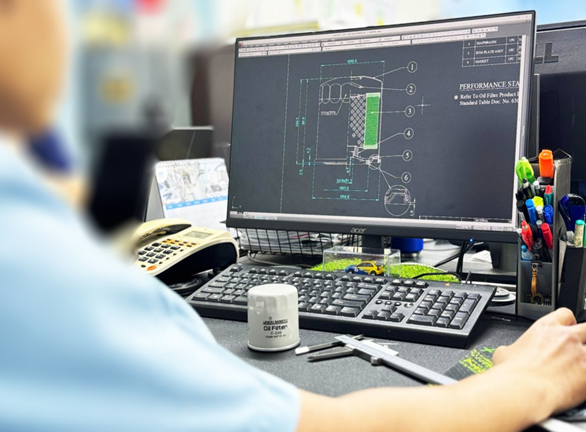

INITIAL PLANNING

Production Environment

INITIAL PLANNING

Production Facilities

Optimized Delivery: Our focus is to reducing lead times and eliminating unnecessary expenses to meet customer demands quickly and efficiently.

INITIAL PLANNING

Product Development

INITIAL PLANNING

New Automation

INITIAL PLANNING

Testing Laboratory